What is Lockout-Tagout?

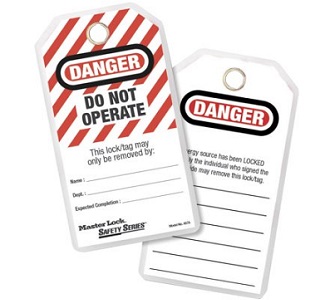

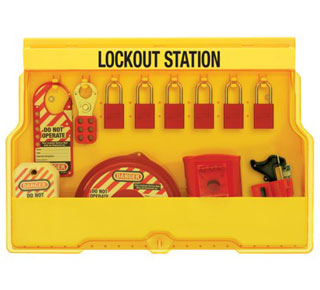

Lockout/Tagout is the process of controlling hazardous energy during the service and maintenance of machinery or equipment. It involves the placement of a lockout padlock, devices and tag on an energy-isolating device, ensuring that the equipment being controlled cannot be operated until the lockout device is removed.

Hazardous energy

Hazardous energy comes in many different forms, all of which are potentially harmful to employees: Electrical, Mechanical, Hydraulic, Chemical, Thermal, Pneumatic or Gravity

Why implement a lockout-Tagout procedure?

An effective LOTO program has immediate impact on the whole organization:

• Reduce the number of injuries & fatalities

• Control of insurance and compensation fees

• Better use of machines : reduce the downtime and improve productivity

• Strengthen workers’ skills

• More committment from employees

• Optimize company reputation

• Improve company’s brand image: socially responsible

OSHA Standards

Many international companies have adopted OSHA standards to control Lockout Program and Procedures. All Master Lock products meet OSHA guidelines. OSHA Standard 1910.147 relates to LOTO and the Control of Hazardous Energy. 4 Key points of the OSHA Lockout standard are:

1 – Devices must be identifiable

2 – Devices shall only be used for controlling energy

3 – Shall not be used for other purposes

4 – Shall meet the following requirements: durable, standardised, substantial, identifiable

Regulations in Europe / Employer responsibilities

Directive 89/655/EEC amended by 2001/45/EC ARTICLE 19 “The employer is commited to guarantee the safety and protection of employees and to take the necessary measures to reduce risks to the minimum possible.” ARTICLE 2.14 « All work equipment must be fi tted with clearly identifi able means to isolate it from all its energy sources . Reconnection must be presumed to pose no risk to the workers concerned .»

7 Step process

Using its knowledge and expertise, Safety Science recommends a 7-step process to effectively lockout equipment.

Step 1: Prepare for shutdown

The authorized person must identify which sources of energy are present and must be controlled; identify what method of control will be used

Step 2: Notify all affected employees

The authorized person communicates the necessary information to notify affected persons.

Step 3: Equipment shutdown

If the system is operating it should be shutdown in its normal manner.

Step 4: Isolation of system from hazardous energy

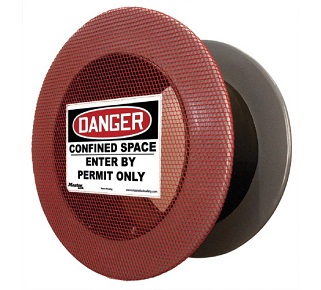

Isolate the energy with a lockout device and ensure complete blockage for the duration of the maintenance operation to prevent any possibility of reactivating the fl ow of energy.

Step 5: Dissipation of residual energy

Identify any stored energy in rams, fl ywheels, springs, pneumatic, or hydraulic systems and make sure it is dissiped.

Step 6: Lockout/Tagout

Lock up the device and ensure it cannot be removed, and the machine cannot be inadvertently operated. • Each lock should only have one key • There should be as many locks on the device as there are people working on it – each of the individuals should place their OWN lock on the system. Locks can only be removed by those who installed them»